Precision solid carbide gear cutting tools

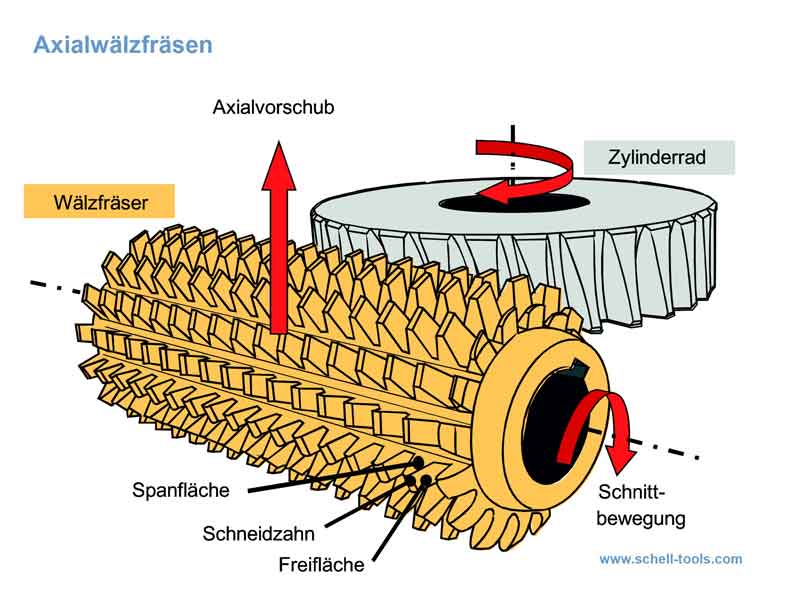

Hobbing is a manufacturing process for gearing and finishing gears. The rotation of the hob cutter generates the actual cutting movement. SCHELL hobs cutters can be used to generate all numbers of teeth, all profile displacements and any angle of inclination.

Gear hobbing is one of the core technologies in gear manufacturing. The quality achieved in this process has a high influence on the following processes such as gear grinding and gear honing.

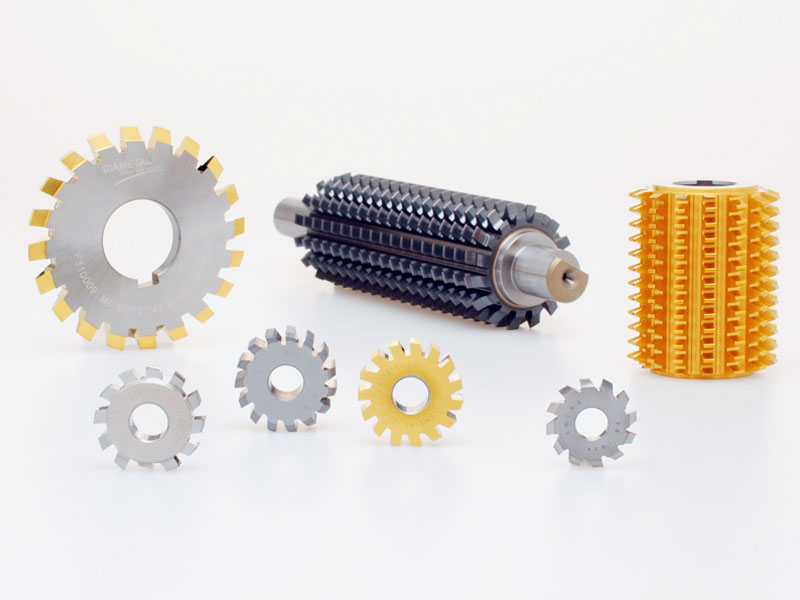

Gear hobs and gear cutting cutters from SCHELL:

- Carbide hob cutters for involute tooth shapes

- Carbide hob cutters for cycloid tooth shapes

- Carbide thread-milling cutter

- Carbide tooth profile

- Carbide setting hobs

- Konrad hob cutters for frontal gear cutting

- Shank hob cutter made of carbide

- Carbide cutters for conical gearing

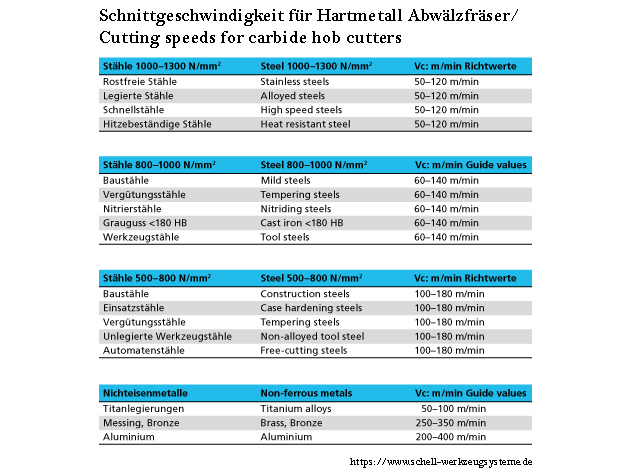

Carbide hobs permit cutting speeds into the high- speed cutting (HSC) range, and significantly higher than those possible with high- speed steel hobs. The development of suitably rated hobbing machines enables the advantages of carbide hobs to be exploited in practical use.

The carbide gear cutting tools from SCHELL are used on hobbing machines from Liebherr, EMAG, FFG, Gleason-Pfauter, Felsomat, Monnier & Zahner, Oerlikon and others.

Please download our 'Gear cutting and hob cutters catalog':

"Carbide gear cutting and hob cutters"

We look forward to your inquiry about our hobs and gear hobs. For this we need a complete description of the workpiece to be machined with the workpiece parameters:

- Module

- Pressure angle

- Helix angle

- Tip circle diameter

- Number of teeth

- Tooth height or root circle diameter

- Profile displacement factor or standards for setting the tooth thickness

- Width of the gear

- Material and tensiles trength