Single and double tooth cutter SCHELL ALUSTAR®

SCHELL ALUSTAR® - THE original: A star on machining center!

Carbide single tooth cutter for aluminum

With lapped flute and extremely sharp cutting edge for machining aluminum and plastic. Due to its special cutting geometry, this milling cutter is ideally suited for processing very soft and sensitive materials. The lapped flute in the single-tooth cutter results in a low coefficient of friction and thus an extremely favorable chip discharge.

SCHELL-ALUSTAR® single-tooth cutters made of solid carbide are suitable for high-speed milling of aluminum profiles on CNC machining centers, copying and model building machines and robotic systems. Very good drilling / dipping properties, for fine machining. Particularly suitable for achieving clear cutting edges when milling Plexiglas and PTFE (Teflon). Only hard metal micrograin quality MG10.5 is used. Right-angled 30 °. The SCHELL-ALUSTAR® single-tooth cutter is also available with a left-hand twist in the flute. Here, the chips are not discharged upwards, but pressed downwards into the milling channel, although the tool is right-cutting. The advantage of the left-hand spin is that the workpiece is also pressed down during processing.

Carbide double tooth cutter for aluminum

- Cutting of non-ferrous metals

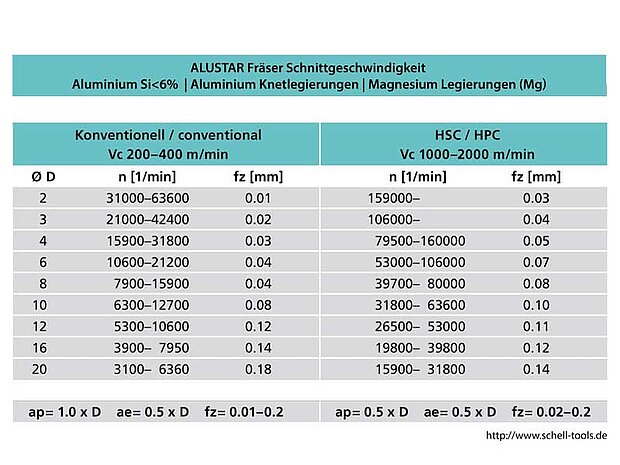

- Cutting speeds up to 3000 m / min

- High time volumes

- HSC / HPC

Due to the extremely sharp carbide cutting edge on the shank drum, best surface finishes are achieved on the work piece with minimum burr formation during milling! Only hard metal micrograin quality MG10 / K40 is used. In addition, the special two-tooth cutters for profiles and thin-walled workpieces are available from stock. Various cutting and overall lengths as well as selectively reinforced shafts allow a wide range of machining possibilities. Twist angle 25 °, center cut.

Please download the catalogue here:

"Single and double tooth cutter SCHELL ALUSTAR"